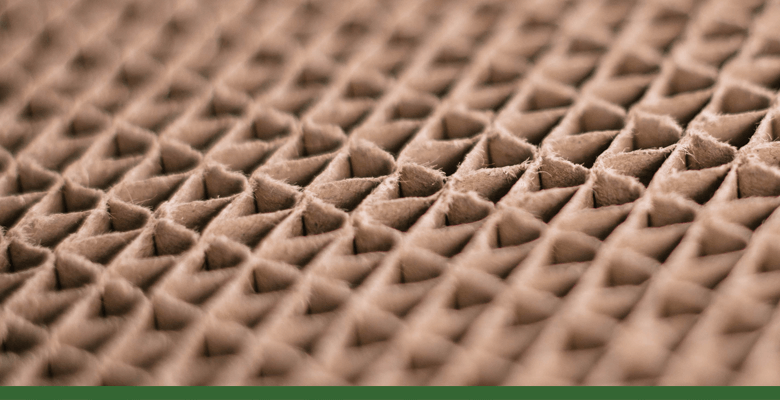

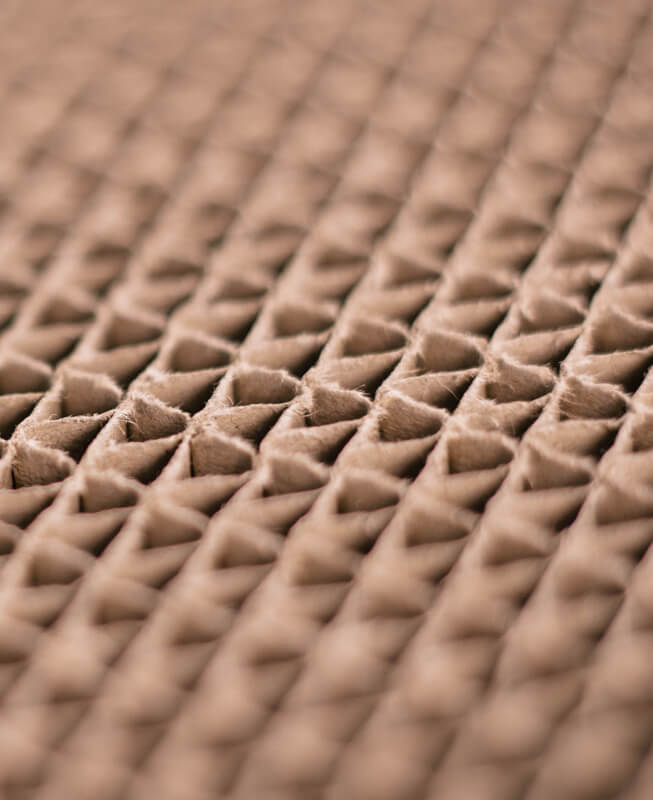

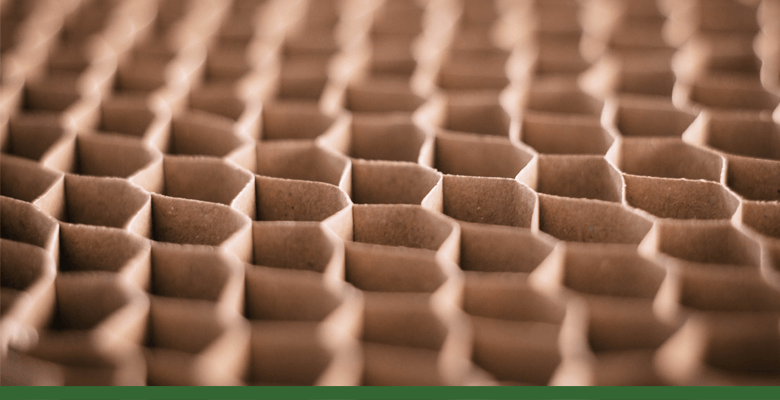

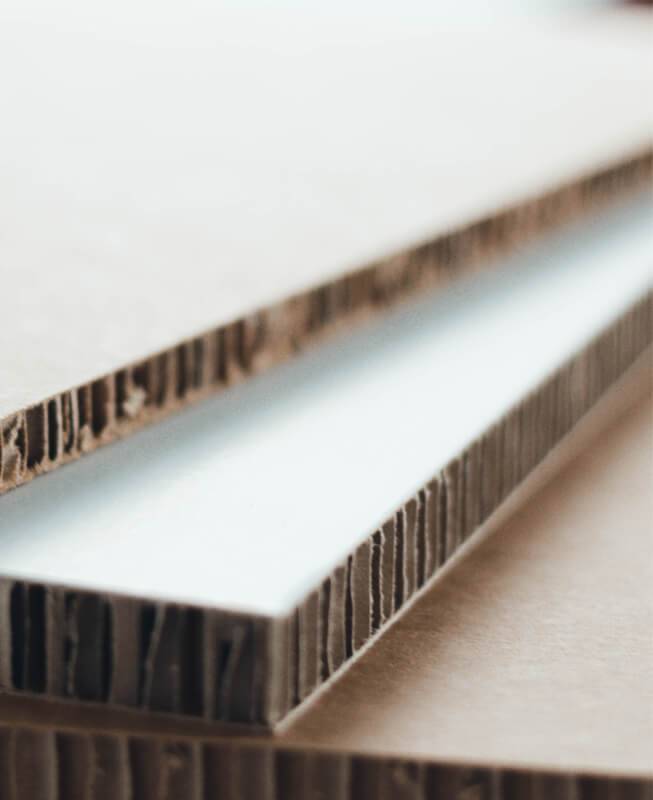

Our medium-sized company produces ecologically sustainable honeycomb boards made of paper. In order to ensure the consistently high quality of the basic and end products, production is carried out using state-of-the-art technology on production lines specially developed by and for SWAP. Production takes place exclusively at our Frankenberg site in Saxony. Eco Future Systems – Made in Germany.

SWAP FUNDAMENTALS.

90 employees

annual sales exceeding EUR 10 million

5,500 tons of annual paper consumption

Customers in Europe, America and Asia

OUR PHILOSOPHY.

SWAP produces ecologically sustainable sinus honeycomb boards from recycled paper. The manufacture and subsequent processing is according to individual customer requirements and permits unlimited possibilities in terms of application.

CAREER AT SWAP.

To reinforce our team we are looking for motivated and committed employees for an immediate start. Your abilities should include being able to work independently and in a team.

SWAP FUNDAMENTALS.

90 employees

annual sales exceeding EUR 10 million

5,500 tons of annual paper consumption

Customers in Europe, America and Asia

ECOLOGICALLY SUSTAINABLE.

OUR PHILOSOPHY.

SWAP stands for honest partnerships and flawless products. Quality and flexibility are our first and foremost priorities. To guarantee this we have our motivated and qualified employees, a healthy work environment, modern machinery and the coordinated and disciplined execution of work processes.

CAREER AT SWAP.

To reinforce our team we are looking for motivated and committed employees for an immediate start. Your abilities should include being able to work independently and in a team. If you have any queries please do not hesitate to contact us.

CERTIFICATES.

INDUSTRY SECTORS

PRODUCTS

COMPANY

REFERENCES

IMPRINT

DATA PROTECTION

DOWNLOADS

COOKIES

Gewerbering 7

D - 09669 Frankenberg